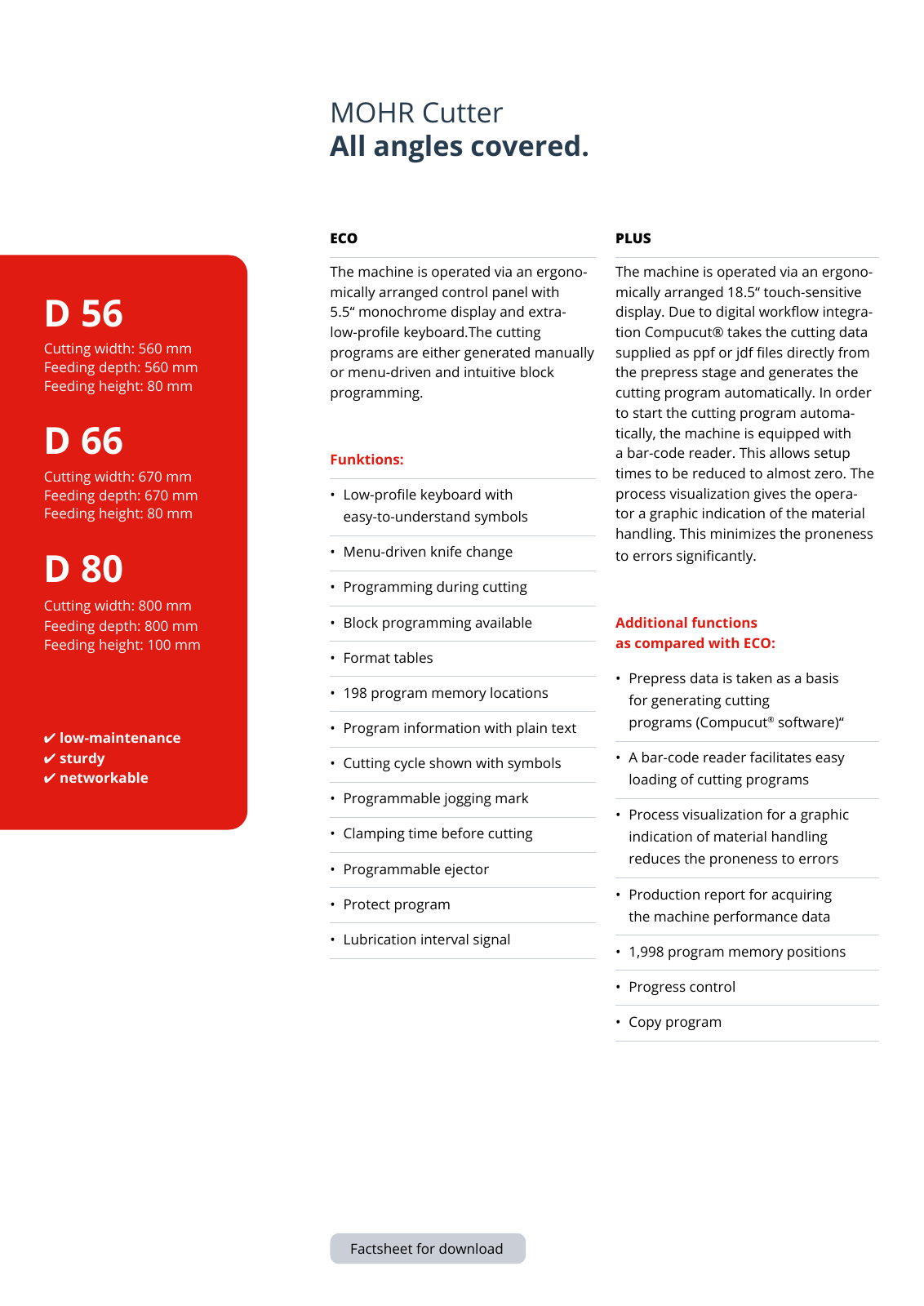

D 56 Cutting width 560 mm Feeding depth 560 mm Feeding height 80 mm D 66 Cutting width 670 mm Feeding depth 670 mm Feeding height 80 mm D 80 Cutting width 800 mm Feeding depth 800 mm Feeding height 100 mm low maintenance sturdy networkable PLUS The machine is operated via an ergono mically arranged 18 5 touch sensitive display Due to digital workflow integra tion Compucut takes the cutting data supplied as ppf or jdf files directly from the prepress stage and generates the cutting program automatically In order to start the cutting program automa tically the machine is equipped with a bar code reader This allows setup times to be reduced to almost zero The process visualization gives the opera tor a graphic indication of the material handling This minimizes the proneness to errors significantly Additional functions as compared with ECO Prepress data is taken as a basis for generating cutting programs Compucut software A bar code reader facilitates easy loading of cutting programs Process visualization for a graphic indication of material handling reduces the proneness to errors Production report for acquiring the machine performance data 1 998 program memory positions Progress control Copy program ECO The machine is operated via an ergono mically arranged control panel with 5 5 monochrome display and extra low profile keyboard The cutting programs are either generated manually or menu driven and intuitive block programming Funktions Low profile keyboard with easy to understand symbols Menu driven knife change Programming during cutting Block programming available Format tables 198 program memory locations Program information with plain text Cutting cycle shown with symbols Programmable jogging mark Clamping time before cutting Programmable ejector Protect program Lubrication interval signal MOHR Cutter All angles covered Factsheet for download

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.